26 May BioMould® – Surface Treatment for Silage

BioMould® – Surface Treatment for Silage

Introduction

Ensiling is a forage preservation method based on spontaneous lactic acid fermentation under

anaerobic conditions. The epiphytic lactic acid bacteria ferment the water-soluble carbohydrates in the crops to lactic acid-, and, to a lower extent, to acetic acid.

epiphytic lactic acid bacteria ferment the water-soluble carbohydrates in the crops to lactic acid-, and, to a lower extent, to acetic acid.

Due to the production of these acids the pH of the ensiled material decreases and spoilage microorganisms are inhibited. Once the fresh material has been stacked and covered to exclude air, the ensiling process can be divided into 4 stages: Initial aerobic phase, fermentation phase, stable phase and feed-out phase or aerobic spoilage phase.

Phase a : Oxygen + Sugar → CO2 + Heat + Water (protein degraded)

Phase b : Sugar → Acetic Acid

Phase c : Sugar → Lactic Acid, Acetic Acid, …

Phase d : Sugar → Lactic Acid, Acetic Acid, …

Phase e : Stable state until silage is exposed to oxygen

A very important factor in this case is the aerobic stability of silage. In the presence of oxygen, yeast

can metabolize lactic acid, a strong acid that keeps the silage pH low. When pH increases,

undesirable fungi and bacteria are able to grow and further spoil the silage. This spoilage results in

dry matter (DM) losses that can be as high as 10% when face management is marginal. Besides a

good silage management there are different possibilities to increase silage quality. One option is to

use different kind of silage additives like organic acids. Farmers frequently chose direct acidification

of silage (complete and/or surface treatment) with acid to immediately lower the pH down to

preserving levels. Acids, like propionic and formic acid, are used most often on crops with moisture

content above 70 percent, on crops with low sugar content-, and on high moisture shelled corn.

Under these conditions, a low pH is needed to prevent clostridial growth.

- Formic acid improves protein preservation of silage by an immediate acidification, which

inactivates protein-degrading bacteria. - Propionic acid improves DM recovery and feedout stability of silage by inhibiting yeast and

mold growth as yeast cannot assimilate propionic acid.

The reduction in yeast numbers is in agreement with the finding that volatile fatty acids such as

propionic acid are much better inhibitors of yeasts than lactic acid.

An effective additive may help make good silage better, but it will not make poor silage good. The

options to create better silage are manifold. One efficient method is surface treatment of silage.

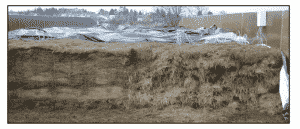

Surface and edge treatment of silage

The treatment of silo surface does not replace complete treatment at ensiling, but, if used properly,

it is an efficient protection against losses at the especially endangered parts of the silo. Spreading

BioMould® on top of the ready to ensile stock is possible, if the silage is sealed air tightly immediately

afterwards. Due to the especial product formulation the acids diffuse slowly from the Vermiculite

lattice (from the carrier) and concentrates below the silage-film. As the acidic vapours cannot escape,

the acids concentrate in the upper layer of the silage and so provide efficient protection.

The recommended dosage is approximately 0.5 [kg / m²].

No Comments